Glass casting process

Glass casting is the process of melting glass into a mold where it solidifies to create a sculpture. The glass casting technique I use to create my sculptures is kiln casting (here you can read about the 7 steps I follow to cast my glass sculptures). Kiln casting enables the creation of intricate shapes inside the glass, which are a result of melting glass into one single pure piece.

Each optical glass sculpture is a unique creation that takes months to complete and involves several stages and techniques. From idea conception to mold making, pieces are then fired in a kiln at 850 degrees Celsius for over a period of two weeks, following a 14-stage temperature monitoring system to ensure uniform cooling. Optical glass requires very slow temperature cooling rates to ensure proper annealing and avoid thermal stress.

Once the firing process is completed, pieces undergo multiple polishing stages to reach optical transparency. This is one of the most time-consuming stages, as each sculpture requires weeks of grinding and polishing to obtain optical transparency.

Sculptures are created using crystal clear, eco-optical glass by OHARA. (Did you know that OHARA glass reached the moon in 1969 aboard Apollo 11?)

The process in pictures

Making the prototype

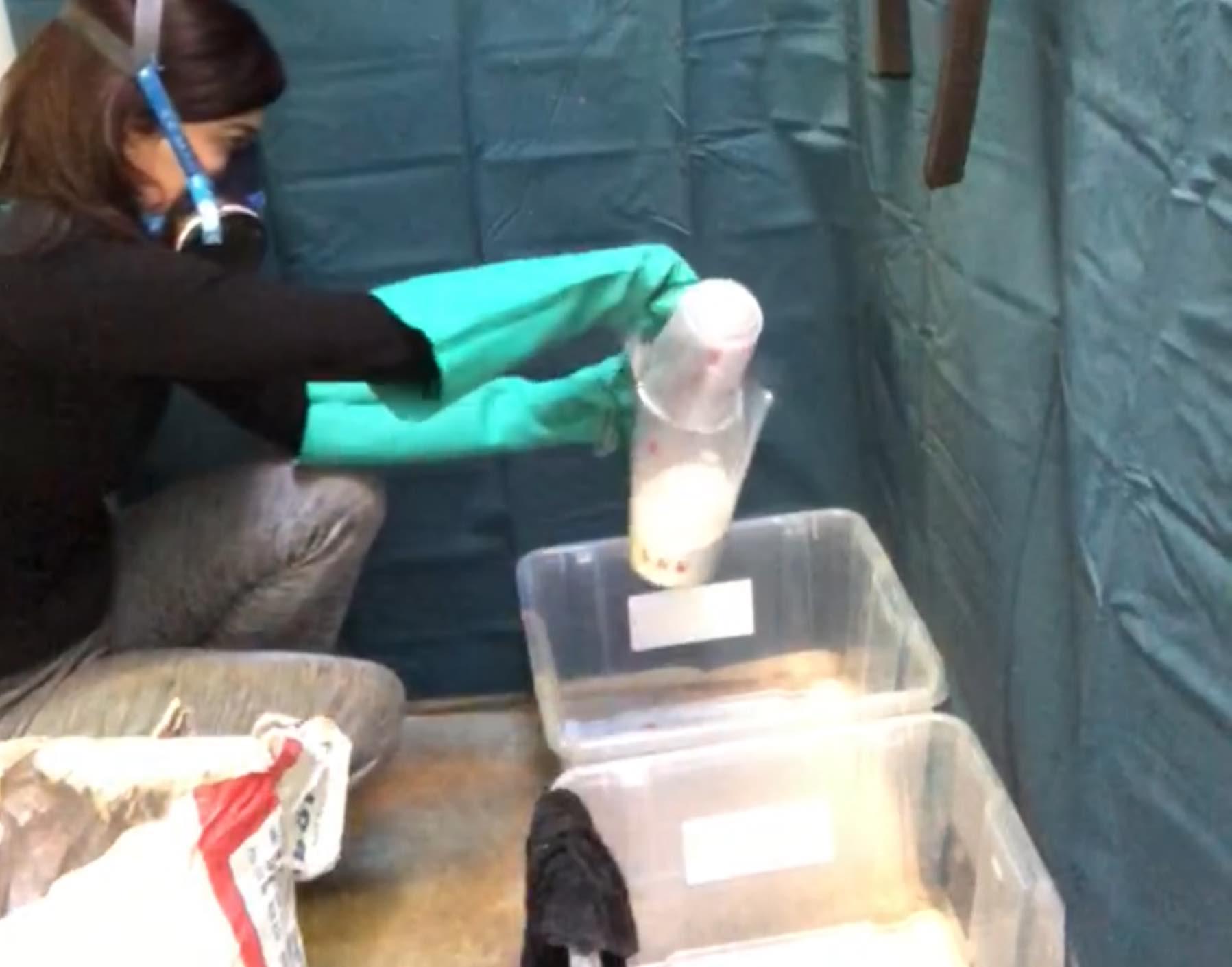

Preparing the plaster mix

Building the walls to pour the plaster mix

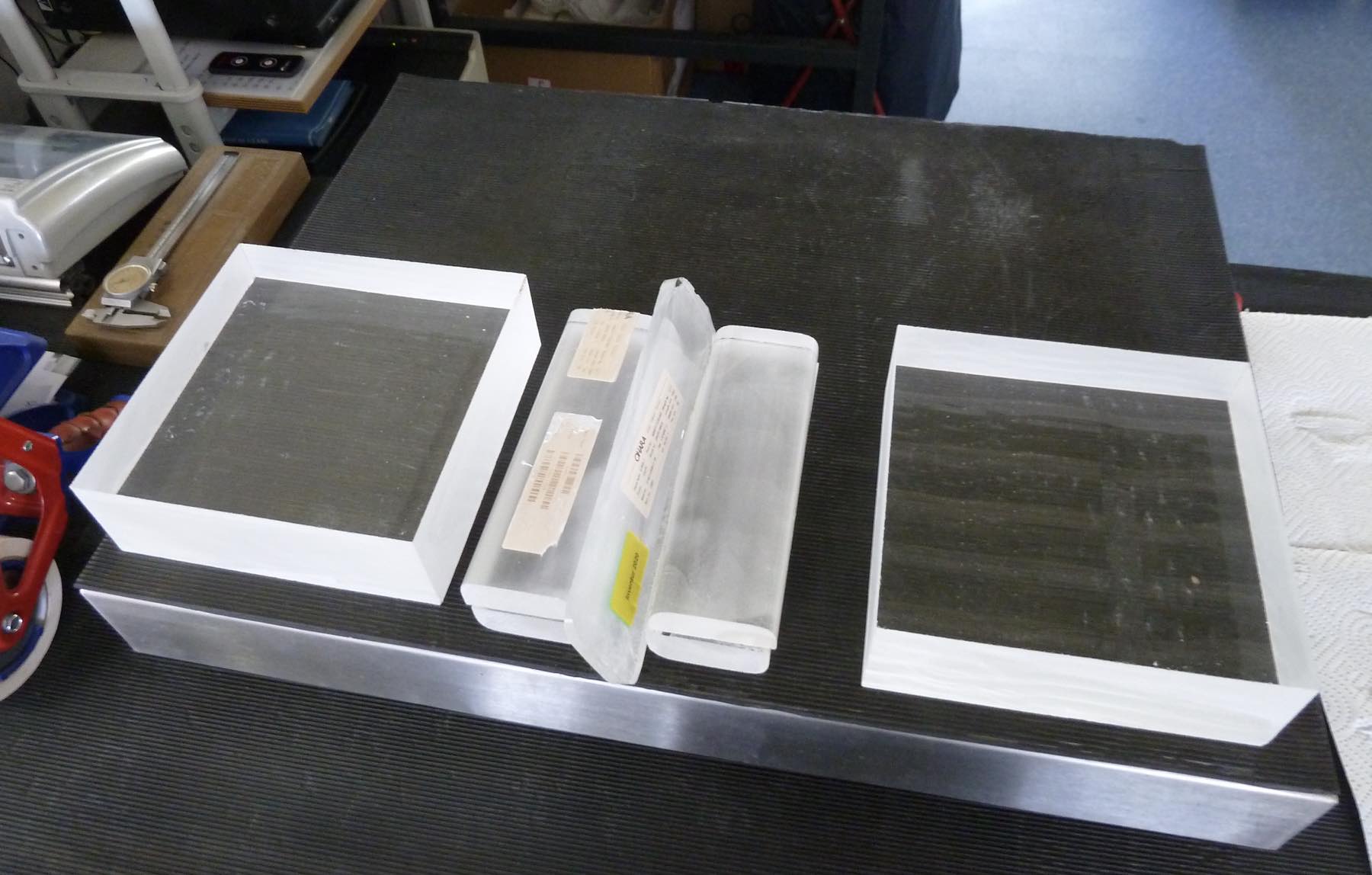

Optical glass blocks prior to melting in the kiln

Mold ready to be fired in the kiln

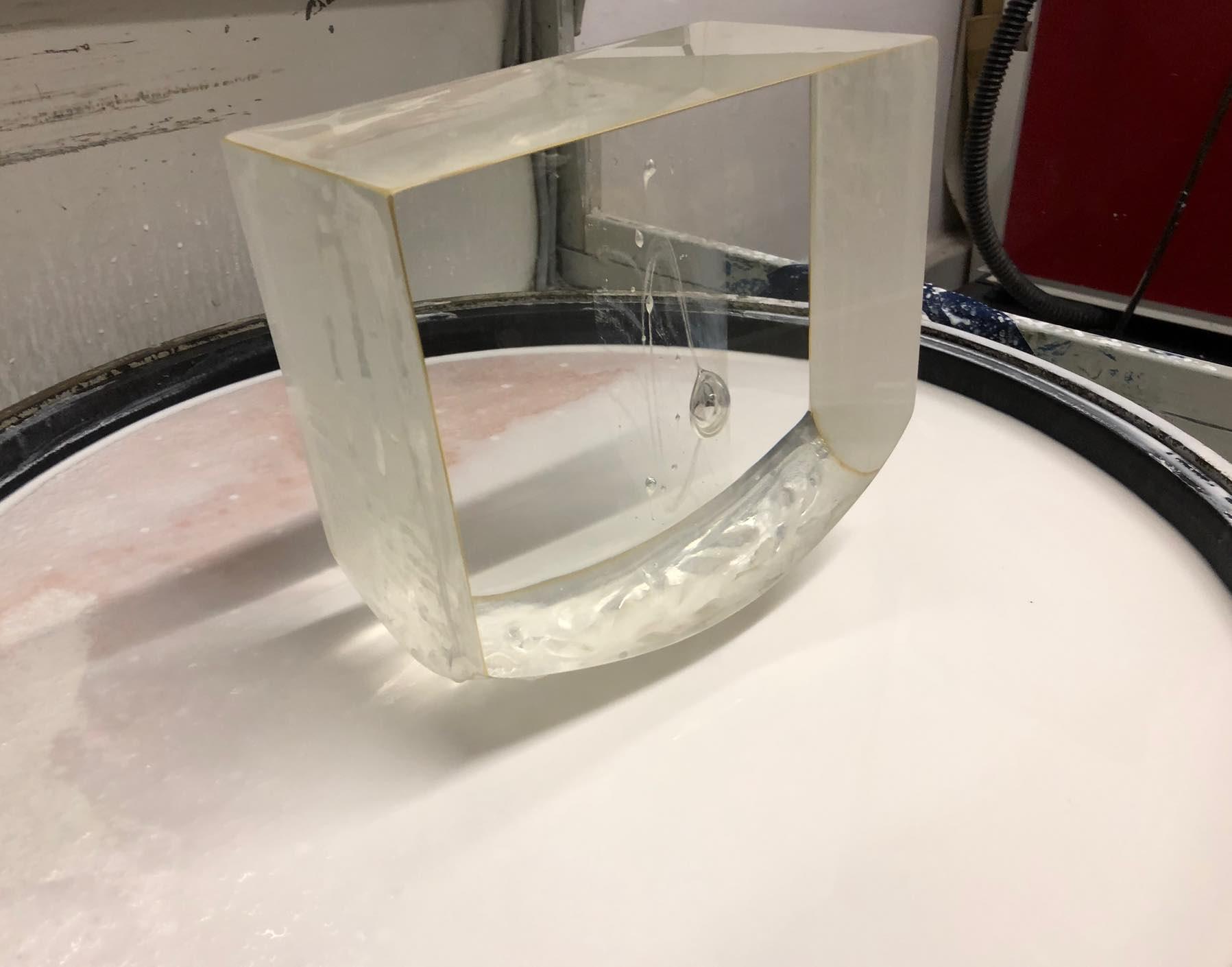

Sculpture after firing and prior to polishing

Grinding a glass sculpture with silicon carbide

Polishing a glass sculpture with cerium oxide