Glass casting process

Glass casting is the process of melting glass into a mold where it solidifies to form a sculpture. This method allows me to create pieces with refined internal detail and optical precision. (Here, you can read about the 7 steps I follow to cast my glass sculptures.)

Kiln casting makes it possible to create complex internal shapes, resulting in a single, seamless piece of solid glass. In my process, every optical glass sculpture is a unique work that takes several months to complete and goes through multiple stages and techniques.

The kiln-casting method

After the initial concept and mold making, the pieces are fired at 850°C in a kiln for about two weeks, following a 14-stage system to ensure uniform cooling. Optical glass requires very slow cooling rates to allow for proper annealing and avoid thermal stress.

Once the firing process is complete, pieces undergo multiple polishing stages to reach optical transparency. This final stage is one of the most time-consuming, as each sculpture requires weeks of grinding and polishing to achieve a flawless, crystal-clear finish.

Each of my glass works is created using OHARA eco-optical glass, a lead- and arsenic-free glass known for its purity and light transmission properties.

The process in pictures

Making the prototype

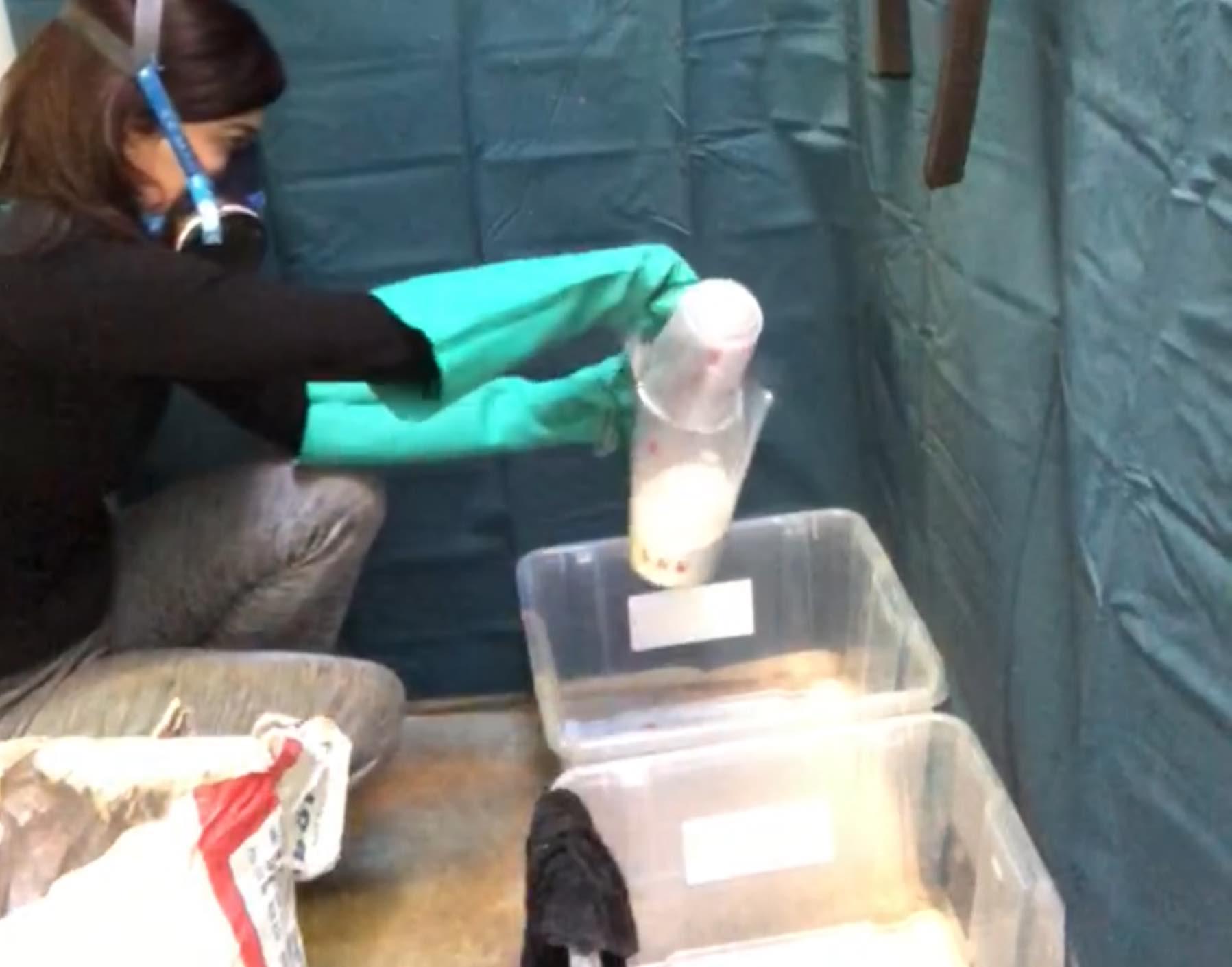

Preparing the plaster mix

Building the walls to pour the plaster mix

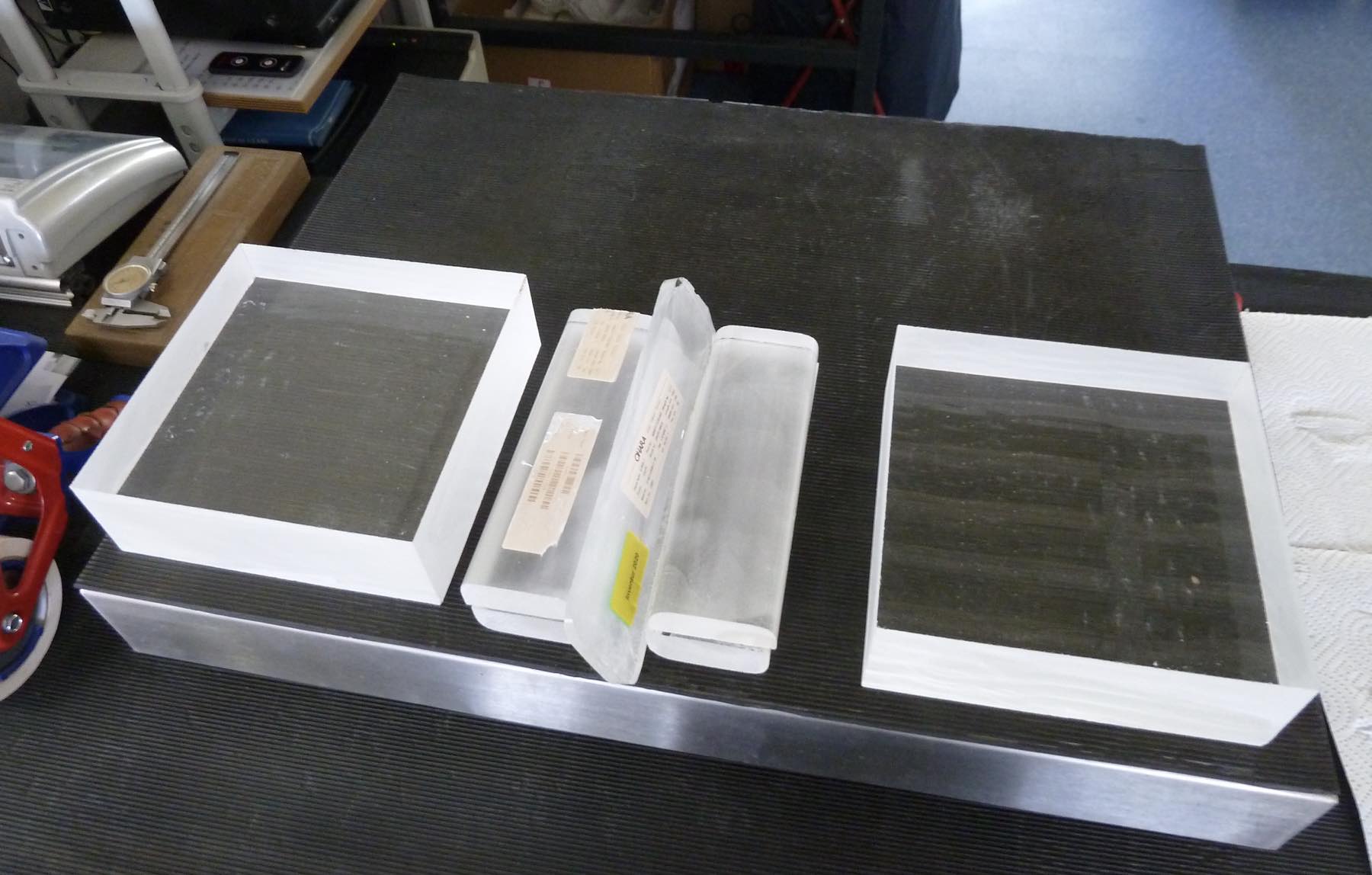

Optical glass blocks prior to melting in the kiln

Mold ready to be fired in the kiln

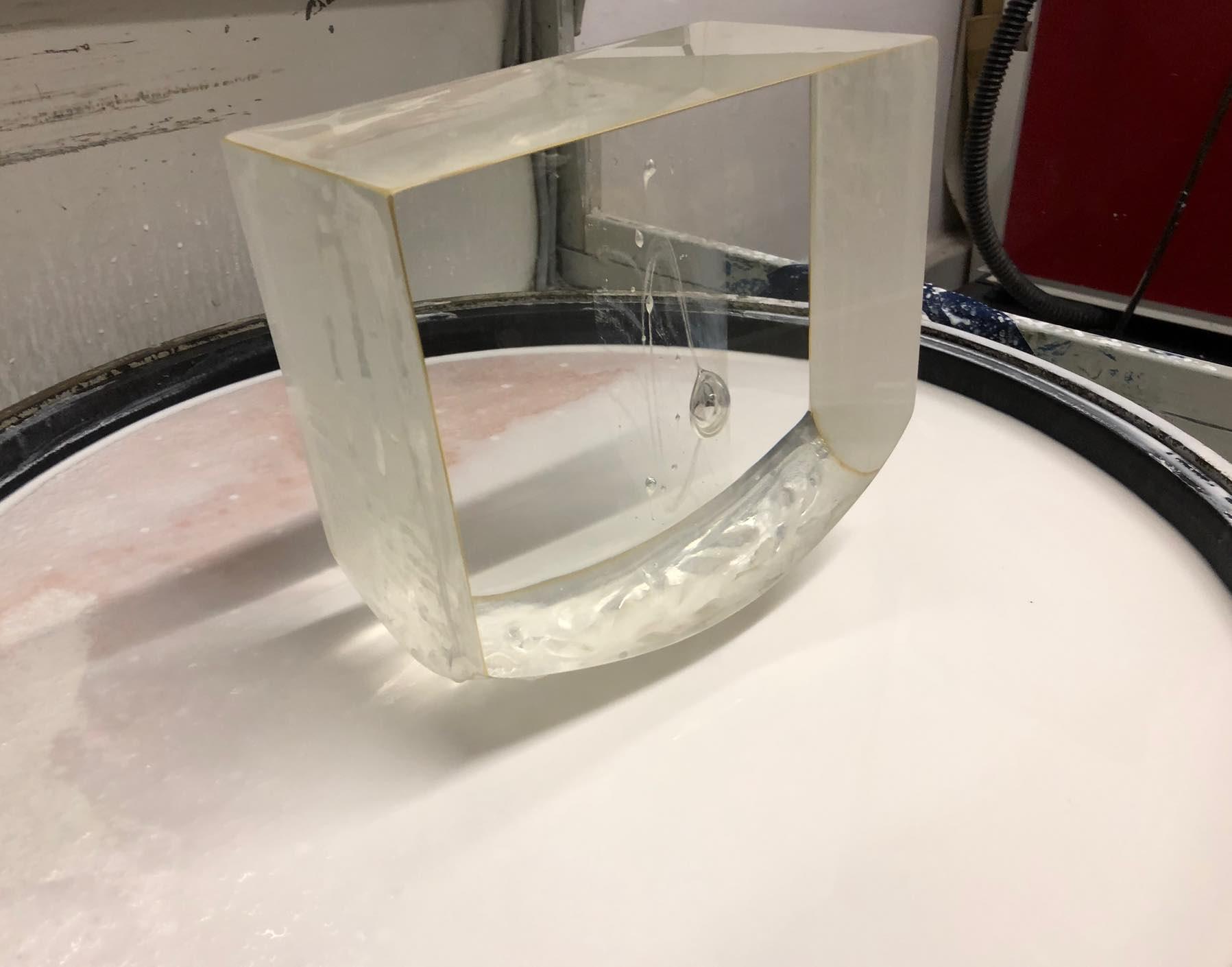

Sculpture after firing and prior to polishing

Grinding a glass sculpture with silicon carbide

Polishing a glass sculpture with cerium oxide